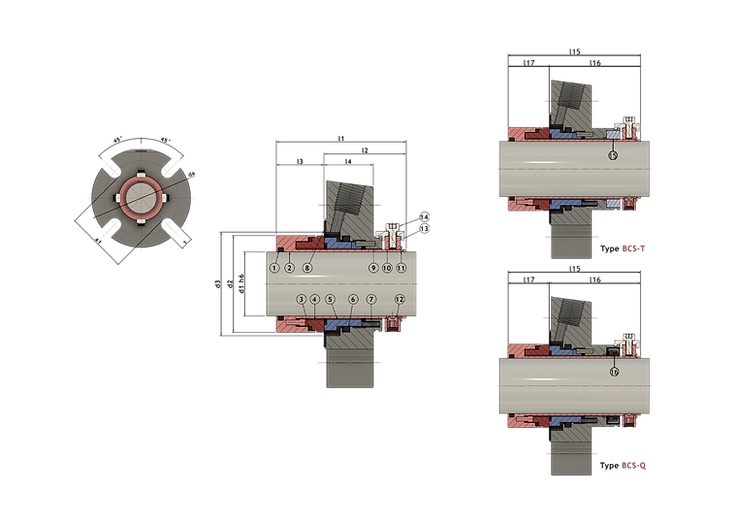

Type BCS-S

Features

Operating range

- Single seal

- Cartridge

- Balanced

- Independent of direction of rotation

- Premium-grade silicon carbide solid seal faces are excellent for

high temperature, high speed pumps and enduring abrasive fluid.

- Universal applicable for packings conversions, retrofits

or original equipment

- No damage of the shaft by dynamically loaded O-Ring

- Extended service life

- Installation faults are avoided, cost-effective

- No damage caused by dirt entered during assembly

- Customer specific versions available

Materials

Rotary Seal Face: SSIC

Stationary Seal Face: SSIC, Carbon graphite resin, Tungsten carbide

Secondary seals: FKM, EPDM, FFKM, Perflourocarbon rubber

Springs: SUS316, Hastelloy® C-4

Metal parts: SUS316

Shaft diameter: d1 = 25 ... 100 mm (1.000" ... 4.000")

Other sizes on request

Temperature: t = –40 °C ... +220 °C (–40 °F ... +428 °F)

(Check O-Ring resistance)

Sliding face material combination Carbon Resin VS SSIC

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination SSIC VS SSIC or TC VS SSIC

Pressure: p1 = 12 bar (174 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Barrier fluid circulation system:

P3max = 25 bar (290 PSI)

P3max = 7 bar (102 PSI) for poor barrier media

Axial movement: ±1.0 mm, d1 ≥ 75 mm ±1.5 mm

Item Item Description

1, 3, 6 O-Ring

2 Sleeve

4 Rotary Seal Face

5 Stationary Seal Face

7 Spring

8 Gasket

9 Gland

10 Set-Ring

11 Lock Washer

12 Set Screw

13 Screw

14 Setter

15 Bush

16 Oil Seal